Tetragonal zirconia also enables the manufacturing of ceramic parts with:

-

Excellent surface finishing

-

Superior wear resistance

-

Outstanding corrosion resistance

Saint-Gobain ZirPro offers world-leading 3mol% yttria-stabilized zirconia powders ranging from dry powder (CY3Z) suitable for injection molding or casting process to ready-to-press granules (GY3Z) used in uniaxial and isostatic pressing or even ready-to-mold feedstock for injection molding of complex parts.

Black pigmented zirconia for decorative fine ceramic applications is also available.

All ZirPro powders are manufactured using a state-of-the-art chemical process to ensure excellent performance and consistent high quality.

ZirPro has developed a CY3Z portfolio that enables to address all needs in terms of applications and ceramic processing:

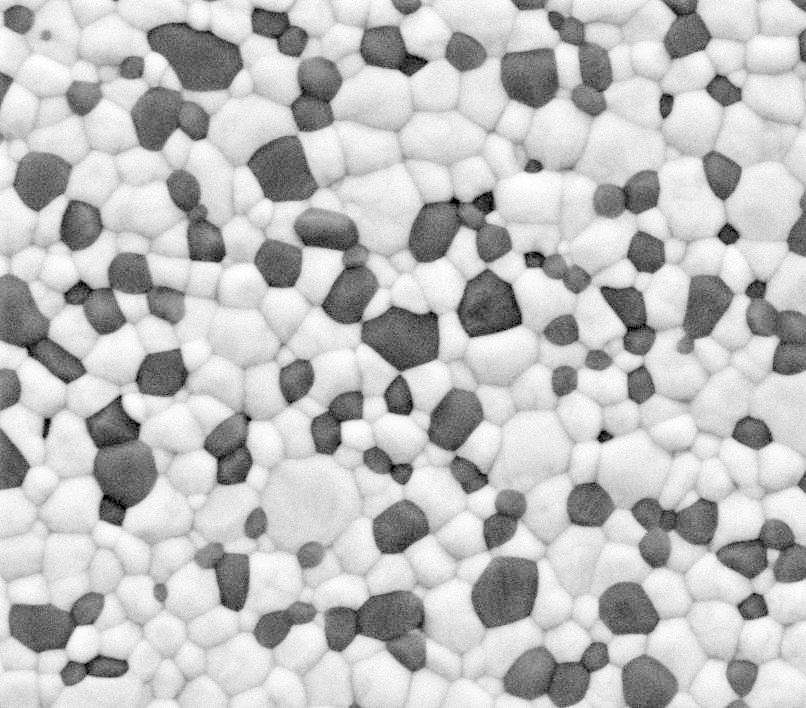

- CY3Z-R grades (specific surface area of 7m²/g), are suitable for the manufacturing of advanced ceramic parts (grinding media, knives, cutting tools,) by injection molding or casting

- CY3Z-M (Specific surface area of 15m²/g) grades are suitable for the manufacturing of small size ceramic parts with very fine microstructure like Optical Fiber Connectors by Ceramic Injection Molding.

All of the powders are made using a state-of-the art chemical process, to ensure high purity (99,99%) and homogeneous sub-micronic particle size.

| CY3Z | ||||

| CY3Z-RS | CY3Z-RA | CY3Z-MS | CY3Z-MA | |

| AI2O3 (wt%) | / | 0.25 | / | 0.25 |

| SSA (m²/g) | 7 | 15 | ||

| D50 (µm) | 0.3 | 0.2 | ||

| Ceramic Density | >6.05 | >6.04 | ||

| Bending Strength (MPa) | >1000 | |||

| Fracture Toughness (Mpa.m1/2) | 5.5 | |||

| Hardness (HV0.5) | 1250 | |||

ZirPro offers 3 mol% yttria-stabilized zirconia ready-to-press granules (GY3Z-R60) that exhibit

- High purity (99.9%)

- Fine and homogeneous particle size

- Advanced binder system

GY3Z-R60 allows the manufacturing of ceramic parts with outstanding mechanical performance.

ZirPro ready-to-press granules are used in advanced technical ceramics thanks to its excellent mechanical performance, excellent pressing ability and green machining.

| GY3Z-R60 | |

| AI2O3 (wt%) | 0.25 |

| SSA (m²/g) | 7 |

| D50 (µm) | 60 (granules) |

| Ceramic Density | >=:6.05 |

| Bending Strength (MPa) | >1000 |

| Fracture Toughness (Mpa.m1/2) | 5.5 |

| Hardness (HV0.5) | 1250 |

The ATZ ColorYZe-Arctic White is suitable either for structural ceramics looking for mechanical performance, or aesthetic ceramics searching for an intense white color.

- Improved hardness resistance compared to standard Y-TZP

- Ceramic with high mechanical performance (Toughness of 6 MPa.M1/2 , Bending strength of 1100MPa).

- Pure white color for aesthetic ceramics

ColorYZe-Arctic White is proposed either as a dry powder (ColorYZe-Arctic White), as ready-to-press granules (ColorYZe-Arctic White -G)..

| ColorYZe-Arctic White | ColorYZe-Arctic White-G | |

| Dry Powder | Ready-To-Press | |

| Y2O3 (wt%) | 4.4 | |

| AI2O3 (wt%) | 20.0 | |

| SSA (m²/g) | 7.5 | |

| D50 (µm) | 0.2 | 60 |

| Ceramic Density | >= 5.50 | |

| Bending Strength (MPa) | 1100 (1900 when HIP) | |

| Fracture Toughness (Mpa.m1/2) | 6 | |

| Hardness (HV0.5) | 1400 | |

| Sintering Recommendation | 1525°C - 2hrs | |